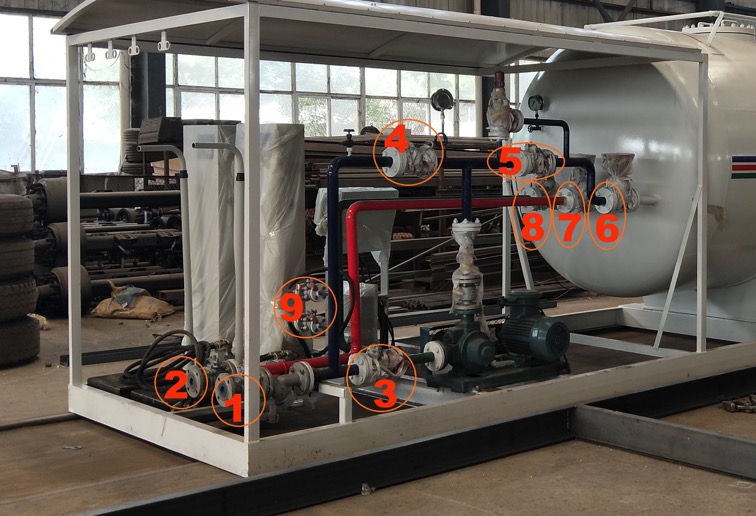

(1) liquid phase valve

(2)gas phase valve

(3)ball valve on liquid pipe

(4)ball valve on liquid pipe

(5)ball valve on liquid pipe

(6)liquid inlet phase valve

(7)gas phase valve

(8)liquid outlet phase valve

(9)liquid outlet phase to filling scale

Process

1, Guide the LPG tank truck or LPG tanker trailer to park at the side of LPG skid station and wait for the driver to pull hand brake ,turn off the car engine, put a anti-slide block behind the wheel!

2, Check the liquid petroleum gas testing sheet, check the liquid ,check the liquid level , pressure and temperature of LPG tanker truck and LPG tank ,check the valve and flange connections for leaks .

3, Connect the electrostatic ground wire ,remove the quick connector cover, connect the gas hose and liquid hose between the LPG skid station and LPG truck (or LPG trailer ) firmly, open the relief valve , evacuate air in the tube with the station liquefied petroleum gas or propane and close the relief valve .

4, Loading gas from LPG TRAILER (or LPG truck) to LPG skid station

a, gas phase system : open the gas outlet of pipe of LPG skid station to the vapor outlet of the LPG tanker (or LPG trailer)

b, liquid phase system: open the valve between the lpg tanker liquid phase and lpg skid station liquid phase .open the tanker emergency shut-off valve and slowly open it when hearing the opening sound .

open the valves :1, 3,5,6,(liquid phase ) 2,7( gas phase ),close other valves

c, start the pump and motor

d, when gas pressure of lpg tank trailer is higher than the receiving lpg skid station 0.2-0.3 mpa ,the liquid flow from the trailer to the lpg skid station . when trailer level close to zero , close the pump and motor timely .close the valve between the LPG trailer and lpg skid station liquid phase ,close the valve between the lpg trailer and lpg skid station gas phase

e, close the lpg trailer (or lpg tank)emergency shut-off valve .remove the hose and static grounding wire after pressure relief ,cover the quick connector cover .

5, Filling the LPG gas from the lpg skid station to cylinders

a, open the valve 8, 4,9,7(liquid phase ) other valves closed

b, start the LPG pump with motor

c, start the lpg filling scale ! The liquid from the lpg skid station through the pump pressurzing !

As a leading LPG skid station manufacturer from China, CLVEHICLES.COM manufacture LPG Skid for filling LPG gas in cars and other vehicles. There are various models available with storage tank capacity, if you are interested in LPG series products, follow us quickly!

Related products: Semi Trailer Truck, Lpg Gas Tank Truck Manufacturer

评论

发表评论