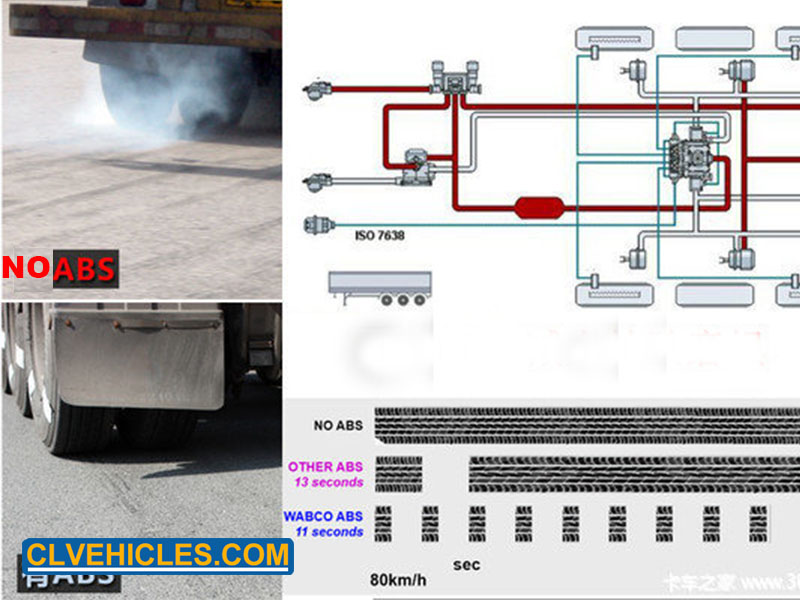

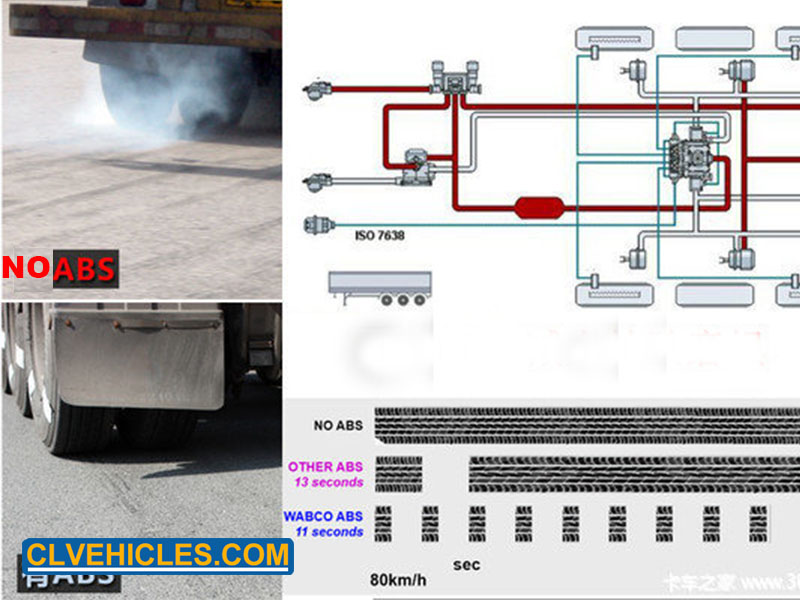

●Misunderstanding 1: Can't stop the vehicles with ABS

The role of the ABS system is to prevent the wheels from locking. Although the ABS system cannot guarantee a shorter braking distance, it can still ensure a certain degree of maneuverability on wet roads or emergency braking, and the vehicle will not get out of control. To a certain extent can ensure driving safety. However, the products of many domestic ABS manufacturers in the early days failed to meet the required braking frequency or there was a problem with the control logic, which directly reduced the braking capacity of the vehicle. During the braking process, the vehicle braking distance was long, giving people Can't stop the vehicles. There are also some ABS products where the wheels are still locked when braking, and have no effect at all.

The misunderstanding that ABS brakes can’t keep the vehicles has a long history. In fact, the ABS system that works normally has no effect on the braking force. ABS works only when the wheels are about to lock up. ABS does not participate in the work, the braking force should still be much, and the braking force will not decrease because of ABS. Therefore, we do not have to stay away from ABS, choose a reliable ABS product, not only to ensure safety to a certain extent, but also save some tires, which is the best of both worlds.

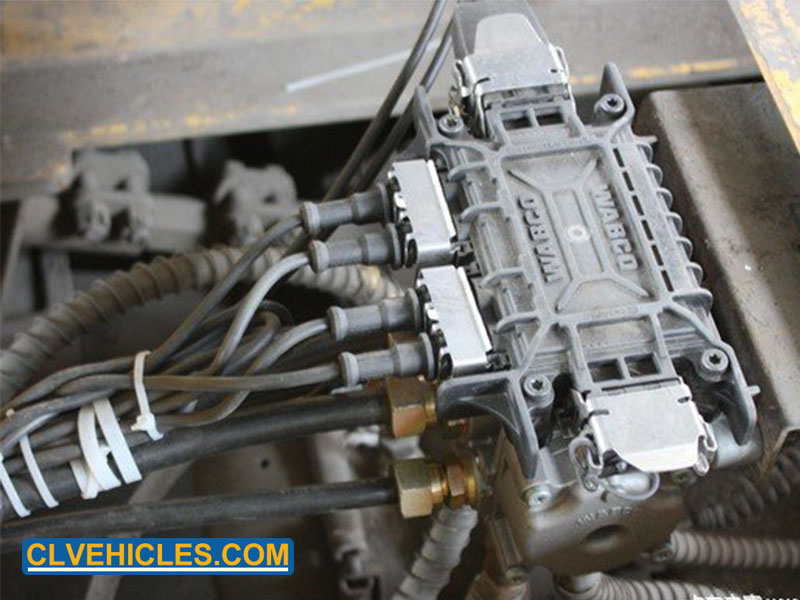

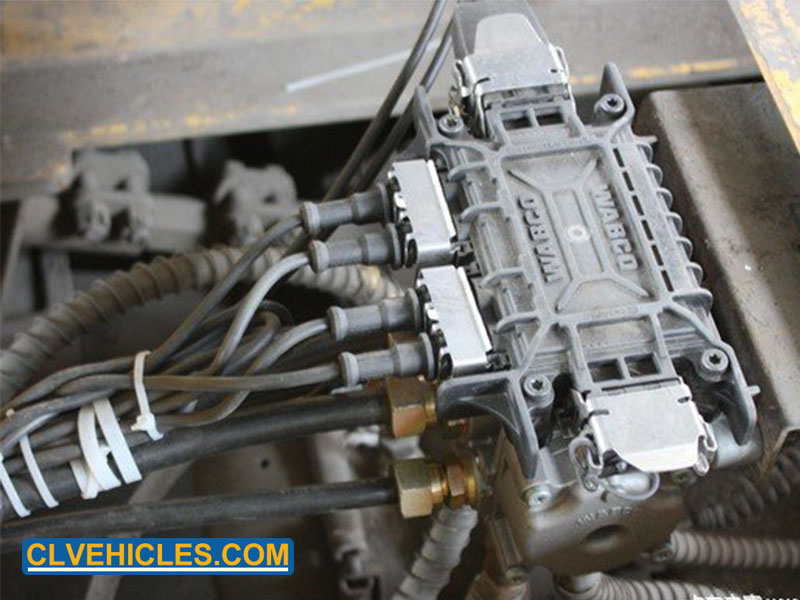

●Misunderstanding 2: With 6-channel ABS, you will not lose control.

For the sake of safety, some drivers have converted their 6x4 tractors and 3-axle trailers into 6-channel ABS systems. Compared with the 4-channel system, the 6-channel system can ensure the safety during braking. However, some drivers are very casual when driving the vehicle after being installed, thinking that this system can ensure safety at any time, relax the line of safety, and there have been some accidents.

In the final analysis, ABS is just a passive safety system. Even a 6-channel system only improves the performance of ABS to a certain extent, making your vehicle safety factor higher, but the vehicle will still appear when the frequency of ABS adjustment is exceeded Out of control. The vehicle is driven by a person, no matter how good the ABS performance is, it only serves as an auxiliary function, which does not mean that you can sit back and relax.

Cvehicles as a truck manufacturer and exporter in China,also supply various special truck spare parts,get detail from us!

The role of the ABS system is to prevent the wheels from locking. Although the ABS system cannot guarantee a shorter braking distance, it can still ensure a certain degree of maneuverability on wet roads or emergency braking, and the vehicle will not get out of control. To a certain extent can ensure driving safety. However, the products of many domestic ABS manufacturers in the early days failed to meet the required braking frequency or there was a problem with the control logic, which directly reduced the braking capacity of the vehicle. During the braking process, the vehicle braking distance was long, giving people Can't stop the vehicles. There are also some ABS products where the wheels are still locked when braking, and have no effect at all.

The misunderstanding that ABS brakes can’t keep the vehicles has a long history. In fact, the ABS system that works normally has no effect on the braking force. ABS works only when the wheels are about to lock up. ABS does not participate in the work, the braking force should still be much, and the braking force will not decrease because of ABS. Therefore, we do not have to stay away from ABS, choose a reliable ABS product, not only to ensure safety to a certain extent, but also save some tires, which is the best of both worlds.

●Misunderstanding 2: With 6-channel ABS, you will not lose control.

For the sake of safety, some drivers have converted their 6x4 tractors and 3-axle trailers into 6-channel ABS systems. Compared with the 4-channel system, the 6-channel system can ensure the safety during braking. However, some drivers are very casual when driving the vehicle after being installed, thinking that this system can ensure safety at any time, relax the line of safety, and there have been some accidents.

In the final analysis, ABS is just a passive safety system. Even a 6-channel system only improves the performance of ABS to a certain extent, making your vehicle safety factor higher, but the vehicle will still appear when the frequency of ABS adjustment is exceeded Out of control. The vehicle is driven by a person, no matter how good the ABS performance is, it only serves as an auxiliary function, which does not mean that you can sit back and relax.

Cvehicles as a truck manufacturer and exporter in China,also supply various special truck spare parts,get detail from us!

评论

发表评论