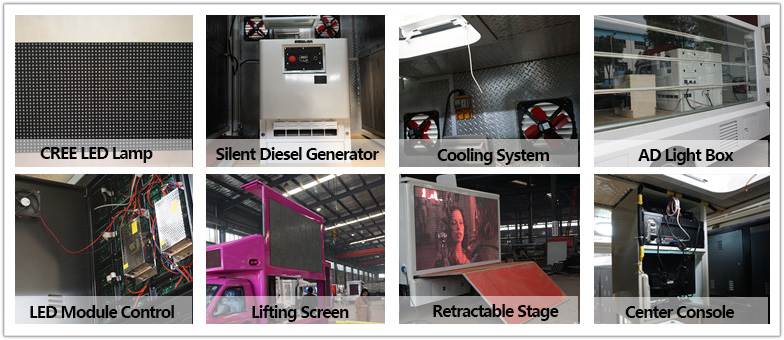

LED screen truck configuration: high-definition LED outdoor full-color screen, LED industrial control computer, high-quality audio and power amplifier, ultra-quiet diesel generator, external power supply; can realize live broadcast, live broadcast, equipped with stage professional audio, and can be used as a small on-site Karaoke singing and other functions.

1) The roof is equipped with a shroud, and there are turn signals, brake lights, and tail lights at the rear of the truck; the surface of the truck body is sprayed with milky white imported paint, and after the whole truck is painted and waxed, the surface is bright and the paint layer is firm, which can be installed in the truck according to user requirements Relevant texts and patterns are pasted on both sides of the body as the logo of the LED advertising truck, which makes the body more beautiful.

2) The truck chassis is provided with shock-proof and heat-insulation treatment. The whole superstructure adopts the steel frame stamping frame; the arc wrapping, the appearance is beautiful and the design is reasonable.

3) The interior of the cabin is luxuriously configured, with two roof windows installed on the top, and the floor is a composite wood floor; the interior of the cabin is comfortable, a strong exhaust fan is installed in the cabin, and vents are installed on the floor to increase the air inside the cabin. cycle.

4) LED screens are installed on the left and right sides of the box, and the screen size is produced according to the actual announcement of the model. The LED screen box adopts a sealed box, which has the effects of shockproof, waterproof and dustproof, and has a long service life.

5) A silent generator is equipped in the cabin, and its exhaust pipe is installed through a flexible shock-absorbing cushion cover. The generator is equipped with a cooling and noise reduction device to prolong the service life of the machine and effectively save fuel consumption. The bottom of the generator is fixed on the chassis of the truck through shock-proof gaskets, and the safety factor is guaranteed.

6) The entire truck line is completely controlled and protected by PVC flame retardant insulating pipes. And install voltage stabilizer, strong and weak current protection device, leakage protection facilities and other safety measures, automatically turn off the power supply of the whole truck when there is leakage.

7) The industrial computer is installed in the truck body, and has a fixed console; the computer is equipped with LED playback software, which can control the playback time and time period of videos and pictures.

8)Playing system: Equipped with high-power amplifier and 4 waterproof speakers, the perfect combination of mid-high and high-pitched, and good sound quality.

9) The rear door is a side-opening door. A monochrome screen is installed on the door. The screen size is: 1280X1600mm (2.05㎡); the rear door is equipped with an anti-theft lock and equipped with a step ladder.

10) A fixed apron is installed under the truck body; an external air conditioner is installed, an external power supply (45m external power cord, can be connected to 220V commercial power at any time), toolbox. https://www.clvehicles.com/

评论

发表评论