The concrete mixer truck is composed of a truck chassis and a special device for concrete mixing and transportation.

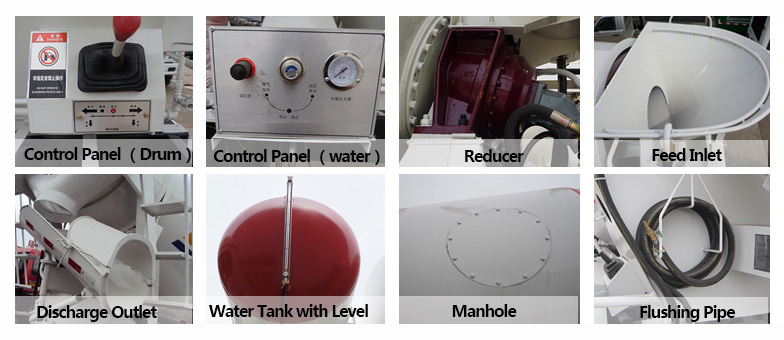

The chassis of the concrete mixer truck mostly adopts the second-class general chassis provided by the chassis manufacturer. Its special mechanism mainly includes power take-off, front and rear brackets of mixing drum, reducer, hydraulic system, mixing drum, operating mechanism, cleaning system, etc.

The working principle is that the power of the chassis is taken out through the power take-off device, and the variable pump of the hydraulic system is driven, and the mechanical energy is converted into hydraulic energy and transmitted to the quantitative motor. The motor then drives the reducer, and the reducer drives the mixing device.

1. Power take-off device

The cement mixer truck adopts the power take-off method of the main truck engine. The function of the power take-off device is to take out the engine power by operating the power take-off switch, and drive the mixing drum through the hydraulic system. Rotate in the opposite direction to cut off the power connection to the engine after the end of the work.

2. Hydraulic system

The engine power taken out by the power take-off is converted into hydraulic energy (displacement and pressure), and then outputted by the motor as mechanical energy (speed and torque) to provide power for the rotation of the mixing drum.

3. The speed reducer decelerates the output speed of the motor in the hydraulic system and transmits it to the mixing drum.

4. Control mechanism

(1) Control the rotation direction of the mixing drum so that it rotates in the forward direction during feeding and transportation, and rotates in the reverse direction when discharging.

(2) Control the rotational speed of the mixing drum.

5. Stirring device

The stirring device is mainly composed of a stirring drum and its auxiliary supporting parts. The mixing drum is a loading container for concrete. When rotating, the concrete moves along the spiral direction of the blade, and is mixed and stirred during the continuous lifting and turning process. During the feeding and transportation process, the mixing drum rotates forward, and the concrete moves inward along the blades. When discharging, the mixing drum reverses, and the concrete is discharged outward along the blades. The blade is the main component in the mixing device, and damage or severe wear will cause uneven mixing of concrete. In addition, if the angle of the blades is not properly designed, the concrete will segregate.

6. Cleaning system

The main function of the cleaning system is to clean the mixing drum, and sometimes it is also used to mix dry materials during transportation. The cleaning system also cools the hydraulic system. https://www.clvehicles.com/

评论

发表评论