With the continuous improvement of

environmental awareness, we continue to raise the emission standards of

vehicles. Under such a trend, the China VI heavy-duty vehicle standard has

officially landed. The formulation of this standard refers to the emission

regulations of heavy vehicles in Europe Ⅵ. Optimized and deepened to achieve a

reduction in NOx and PM emissions. At the same time, by controlling emissions

in actual use, transparency of pollutant emissions also contributes to

environmental supervision.

In terms of emission limits, according to the mature emission control technology in China, the sixth stage of heavy vehicle pollutant emission goal is to reduce nitrogen oxides NOx and PM by more than 60%. At the same time, the particulate matter bulk (PN) limit should also be reduced by about 33%.

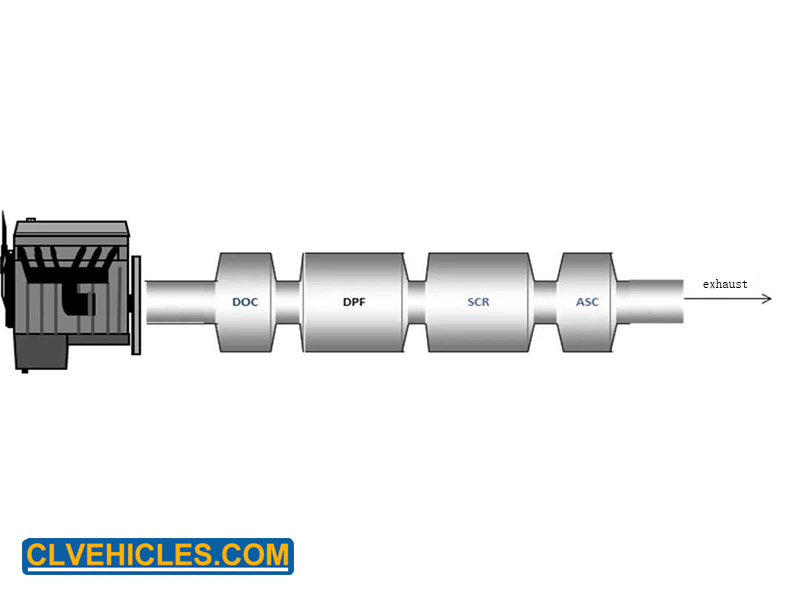

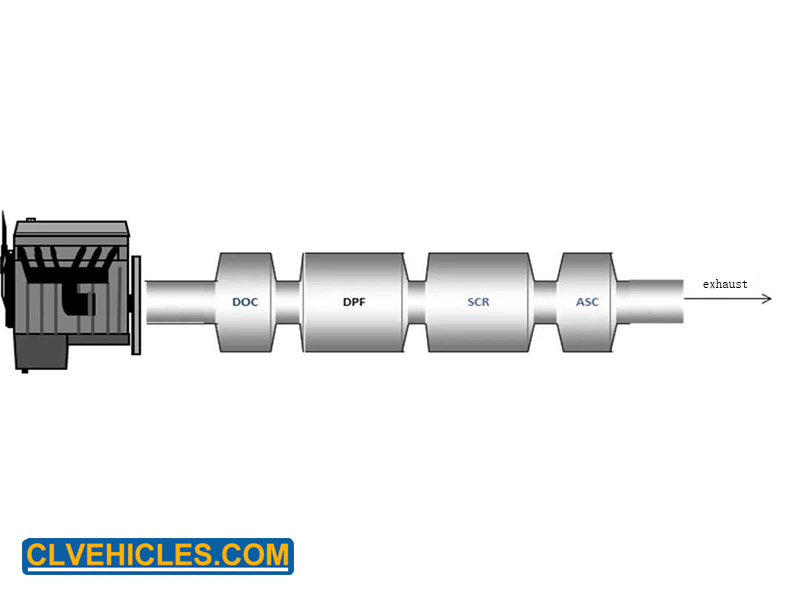

With the upgrade of China VI emissions, it is well known that the after-treatment of China VI becomes more complicated. In addition to the SCR system of China V, there are more DOC, DPF and ASC for purification outside the aircraft.

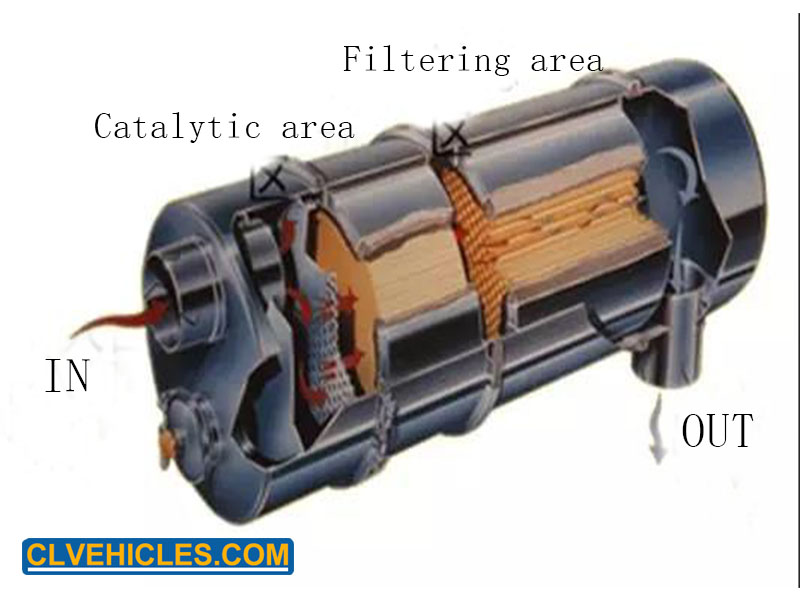

DOC oxidation catalytic converter

DOC catalytic oxidation can reduce CO and HC emissions in diesel exhaust. In short, the products that are not completely burned are further oxidized to produce CO2 and H2O. Of course, this is conditional, the appropriate temperature (200 ℃ ~ 400 ℃), and the role of catalyst (precious metals such as platinum Pt, palladium Pd) are necessary!

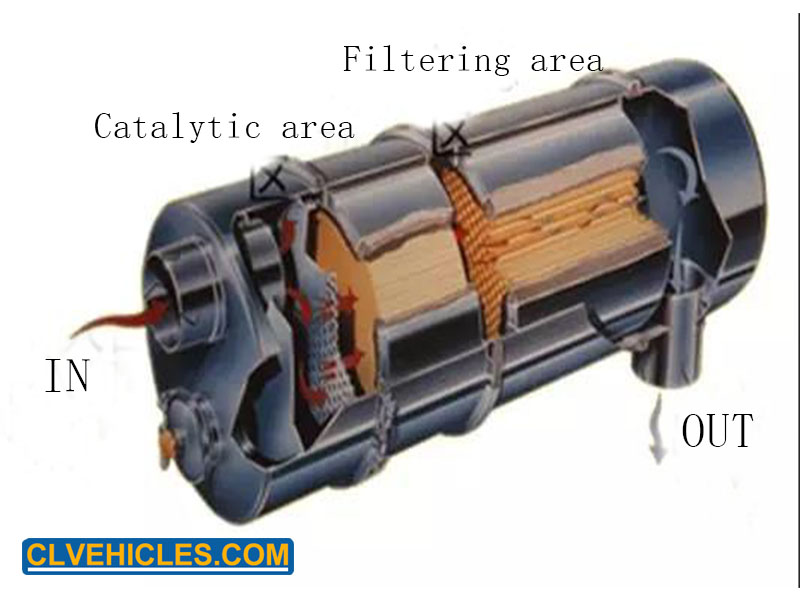

DPF wall-flow particle trap

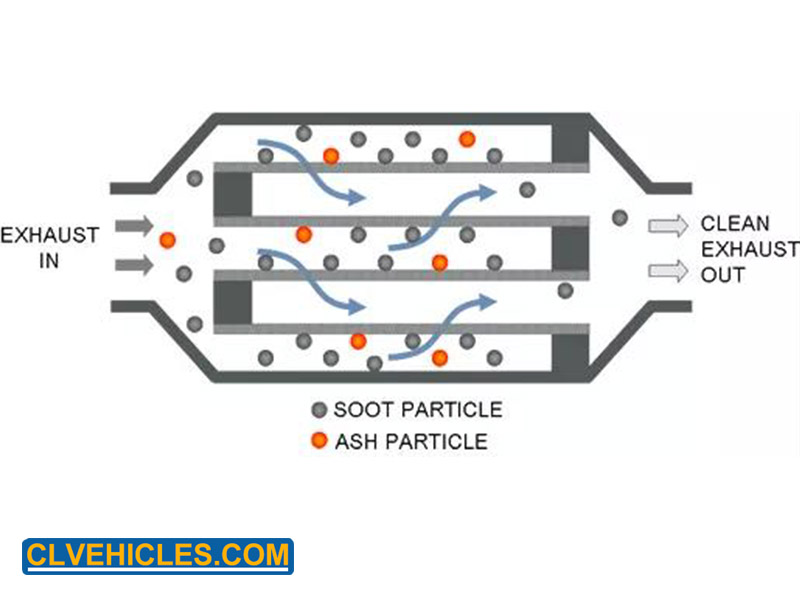

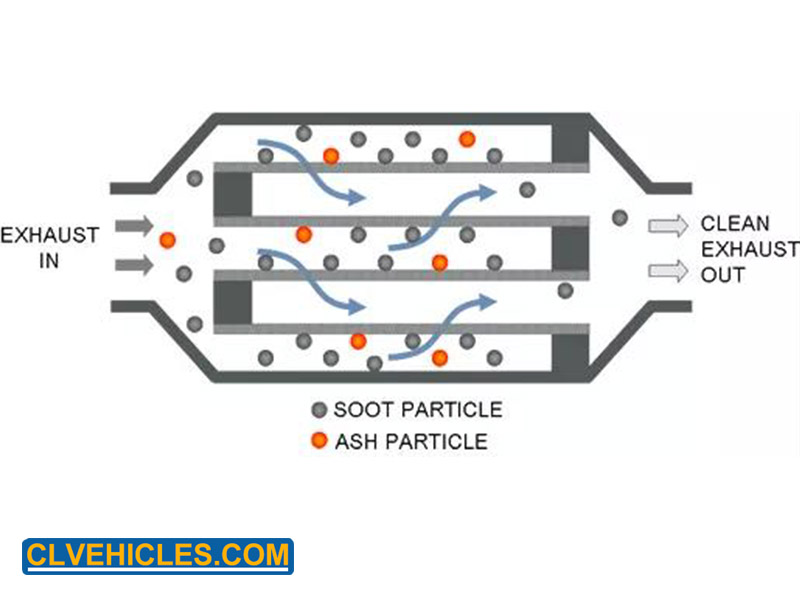

The role of the DPF wall-flow particle trap is, in short, a device that filters out both large and small particles. It relies on alternately blocking the inlet and outlet of the carrier hole to force air flow through the porous wall to achieve particle capture. At present, other post-processing devices, such as SCR and DOC, are very smooth, so there is no direct interception function for particulate matter PM.

China VI puts forward stricter standards for CO and HC emission requirements. At the same time, China VI also puts forward requirements for the original NOx emissions (pre-concentration of post-processor). The relationship between the original NOx emissions and CO and HC emissions is a trade-off, so this is also one of the reasons why the National Six diesel engine is equipped with DOC. Of course, raising the exhaust temperature through the internal reaction of the DOC is also crucial to the DPF.

Related products: truck chassis spare parts, truck upper body spare parts.

In terms of emission limits, according to the mature emission control technology in China, the sixth stage of heavy vehicle pollutant emission goal is to reduce nitrogen oxides NOx and PM by more than 60%. At the same time, the particulate matter bulk (PN) limit should also be reduced by about 33%.

With the upgrade of China VI emissions, it is well known that the after-treatment of China VI becomes more complicated. In addition to the SCR system of China V, there are more DOC, DPF and ASC for purification outside the aircraft.

DOC oxidation catalytic converter

DOC catalytic oxidation can reduce CO and HC emissions in diesel exhaust. In short, the products that are not completely burned are further oxidized to produce CO2 and H2O. Of course, this is conditional, the appropriate temperature (200 ℃ ~ 400 ℃), and the role of catalyst (precious metals such as platinum Pt, palladium Pd) are necessary!

DPF wall-flow particle trap

The role of the DPF wall-flow particle trap is, in short, a device that filters out both large and small particles. It relies on alternately blocking the inlet and outlet of the carrier hole to force air flow through the porous wall to achieve particle capture. At present, other post-processing devices, such as SCR and DOC, are very smooth, so there is no direct interception function for particulate matter PM.

China VI puts forward stricter standards for CO and HC emission requirements. At the same time, China VI also puts forward requirements for the original NOx emissions (pre-concentration of post-processor). The relationship between the original NOx emissions and CO and HC emissions is a trade-off, so this is also one of the reasons why the National Six diesel engine is equipped with DOC. Of course, raising the exhaust temperature through the internal reaction of the DOC is also crucial to the DPF.

Related products: truck chassis spare parts, truck upper body spare parts.

评论

发表评论